12

2023

-

04

Precautions for using closed-circuit cooling towers

Author:

Closed-circuit cooling tower Precautions for use

I. Usage environment

★ Avoid acidic exhaust gas, explosive dust, heavy coal smoke, and excessive water vapor areas:

★ When placed next to buildings, maintain a sufficient distance from the air intake (0.5-3 meters, depending on the model)

★ When placed in a well-type enclosure, be wary of the return of humid hot air causing heat dissipation failure. A draft device can be considered for special environments.

II. User piping issues

★ Piping and valves should be installed below the operating water level of the cooling tower to prevent overflow and air intake:

★ When considering the equipment placement, the water pump should have sufficient head, and the pressure loss along the way and the pressure loss of the cooling coil should be considered:

★ The fluid cooling interface flange is designed for 1Mpa, and all pipelines should consider hangers or supports.

III. Maintenance requirements of the spray system

★ With Closed-circuit cooling tower operation, minerals and other impurities in the water will precipitate and accumulate in the sump. Therefore, regular inspection and periodic drainage cleaning are necessary to better control water quality and prevent scaling.

★ Spray water quality requirements: Refer to the "Design Code for Industrial Recirculating Cooling Water Treatment". In areas with particularly poor water quality, water purification (softening) treatment should be considered.

IV. Replenishment of circulating water

★ Spray water replenishment:

Evaporation ≤ 0.8% of the flow rate + Drift rate ≤ 0.1% + Discharge rate ≤ 0.3% = ≤ 1.2% of the circulating flow rate

★ The circulating water in the closed system should meet the water quality requirements of the production process, and softened water or pure water can be used.

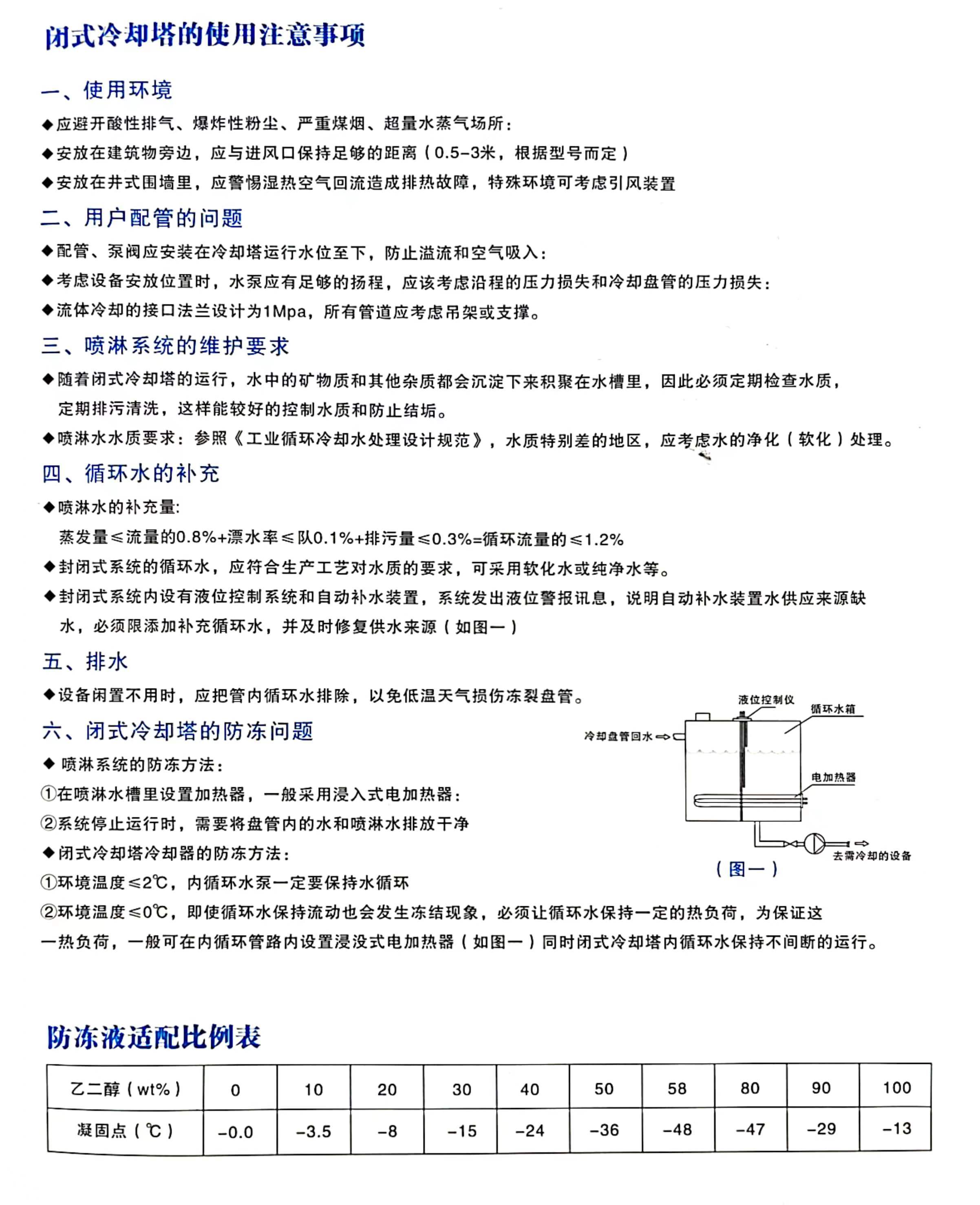

★ The closed system is equipped with a liquid level control system and an automatic water replenishment device. If the system issues a liquid level alarm message, it indicates that the water supply source of the automatic water replenishment device is lacking water. It is necessary to limit the addition of supplementary circulating water and repair the water supply source in time.

V. Drainage

★ When the equipment is idle, the circulating water in the pipe should be drained to prevent the coils from being damaged and cracked by freezing in cold weather.

VI. Closed-circuit cooling tower Anti-freezing issues

★ Anti-freezing methods for the spray system:

① Install a heater in the spray sump, generally using an immersion electric heater:

② When the system stops running, the water in the coils and the spray water need to be drained.

★ Closed-circuit cooling tower cooler Anti-freezing methods:

① When the ambient temperature ≤ 2℃, the internal circulating water pump must maintain water circulation.

② When the ambient temperature ≤ 0℃ ≤ 0℃, freezing will occur even if the circulating water keeps flowing. The circulating water must maintain a certain heat load. To ensure this heat load, an immersion electric heater is generally installed in the internal circulation pipeline, and at the same time Closed-circuit cooling tower the internal circulating water keeps running continuously.

Cooling tower,Closed-circuit cooling tower,Spray tower,chiller,Evaporative cooling

12

2023-04

Precautions for using closed-circuit cooling towers

03

2023-01

03

2023-01

03

2023-01

What are the roles of cooling tower components in cooling tower renovation?

03

2023-01

03

2023-01

Service Hotline:

+86-138 2574 5855

+86-189 0261 0628

E-mail:dykj1688@yeah.net

Address: Guangdong Province, Huizhou City, Boluo County, Longxi Town, Longyuan Avenue, Dongyan Technology Industrial Park

Follow us

Scan with your phone

Copyright © Guangdong Dongyan Cooling Equipment Co., Ltd. All rights reserved.

Power by:www.300.cn | SEO | Privacy Policy